Meals, Ready-to-Eat, Set the Standard for Military Rations

If you cooked a meal, stored it in a stifling hot warehouse, dropped it out of an airplane, dragged it through the mud, left it out with bugs and vermin, and ate it three years later, nothing would happen-if it were an MRE.

The Meal, Ready-to-Eat (MRE) has evolved over years of intense research and product development to be what's considered the finest operational ration in the world today. It has helped make the U.S. military the best-fed fighting force in the world.

The MRE, which replaced the canned Meal, Combat Individual (C Ration) in the early 1980s, is the current standard individual military operational ration.

The MRE is a totally self-contained, flexibly-packaged meal used by U.S. soldiers and Marines in the field. It is used by the services to sustain individuals during operations that prevent organized food service facilities but where resupply is established or planned.

Modern operational requirements demand ration systems that adequately provide for the needs of the individuals in extremely intense and highly mobile combat situations. The MRE answers that demand as no other ration in history.

Fighter fuel

The logistical task of providing subsistence for military personnel has been critical throughout history. Frederick the Great of Prussia is credited with having defined an army as a group of men who demand daily feeding.

Military rations are no less important today. In fact, the importance of sound nutrition to the performance of modern military personnel may be even more critical than in the past. Food fuels the fighter, and inadequate fuel for fighters will bring the military machine to a grinding halt.

The U.S. Army Soldier and Biological Chemical Command's Soldier Systems Center (SSC) at Natick, Mass., is home to the Department of Defense (DoD) Combat Feeding Program, which is responsible for the design, development and testing of all military rations for the Armed Forces.

The Combat Feeding Program encompasses the design, development and evaluation of new and improved operational rations, packaging, food service equipment and feeding systems.

|

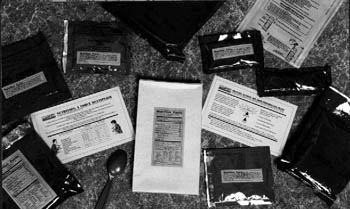

The Meal, Ready-to-Eat provides troops in the field with a complete, nutritious meal that can withstand extreme conditions. |

Natick manages the research, development and engineering, which provides the science and technology base and the engineering support to satisfy the unique feeding requirements of each military service critical for operational success.

A joint technical staff, composed of representatives from each of the four services, functions as the primary interface between Natick and the services in preparation and execution of a prioritized and integrated research, development, and engineering program.

Product requirements

Numerous constraints and considerations must be addressed if an acceptable ration product is to be provided to American military personnel.

Ration development constraints include nutrition, personnel acceptance, wholesomeness, producibility, cost, shelf life, self-heating capability, modularity, weight, volume, ease of sanitation, menu fatigue and performance enhancement.

|

MREs include convenience items along with a variety of commercially-available drink mixes and snack foods. |

In addition, MRE packaging must meet stringent durability requirements to include airdrop, rough handling and brutal temperature extremes.

Research and development breakthroughs have made it possible for MREs to be lightweight, compact, easily opened, withstand a parachute drop from 1,250 feet or from a helicopter at 100 feet with no parachute, endure inclement weather and survive temperature extremes from minus 60 degrees Fahrenheit to 120 degrees Fahrenheit.

They must have a minimum shelf life of three years at 80 F and last for six months at 100 F, be highly acceptable and meet the Office of the Surgeon General's nutritional requirements as identified in Army Regulation 4025, Nutritional Standards for Operational Rations.

|

MRE pouches are made out of several layers of material and are like a flexible can. They have better storage and distribution qualities than a can, without the weight or need for a can opener. |

MRE contents

Each meal contains approximately 1,200 calories and includes an entrée or starch; crackers; a cheese, peanut butter or jelly spread; a dessert or snack; beverages; an accessory packet; a plastic spoon and a flameless ration heater (FRH). The FRH is a water-activated exothermic chemical heater designed to heat the entree of an MRE by raising the temperature of the 8-ounce entree by 100 F in 12 minutes.

The FRH has proven to be an effective method for the individual soldier to obtain a hot meal on demand in the field. Since assembly of MRE XIII, one FRH has been included in each MRE meal bag. The MRE flexibly packaged foods are heat-processed in retortable pouches. Retort describes a thermostabilization process much like canning. The pouch is made out of several layers and is like a flexible can but has better storage and distribution qualities than a can, without the weight or need for a can-opener.

The pouch is filled with the food and then sterilized in large pressure-cooker-like equipment. This process gives the product a long shelf life and helps retain natural juices and flavors for greater acceptability.

The number of menus increased incrementally from 12 to 24. Four vegetarian meals are now included (two in each case), a new easy-open meal bag with commercial-like colors and graphics have been added, nutritional labeling implemented and application of Time Temperature Indicator (TTI) labels included on MRE ration cases. TTIs will facilitate rapid and effective quality monitoring and stock management of pre-positioned MREs.

Foxhole to grocery store

Many of the products and packaging innovations and developments during the past 40 years, which we take for granted yet appear on our grocery store shelves, have their roots in military ration research. Many new technologies and items were developed during this period to meet changing military feeding situations and to accommodate the increasing demand for mobility and dispersion of combat forces. Products created by military-sponsored research have traveled from the foxhole to the grocery store and your kitchen table.

Some of these technology "spin-off" items used extensively by the commercial food industry for public benefit include freeze dehydrated meats, processed cheese, dehydrated egg and milk products, edible coatings, dry soup and similar mixes, converted rice, restructured meats, frozen entrees, freeze dried foods and coffee, dry beverage mixes and shelf stable bakery products.

Changing menu

Under the auspices of the Combat Feeding Program, research and development efforts since Operation Desert Storm have implemented significant customer-driven improvements to the MRE.

These improvements include expanding variety and improving acceptability, consumption and nutritional intake to enhance performance on the battlefield while minimizing weight and volume. All changes to the MRE menu undergo a battery of laboratory tests, and sensory and operational evaluation with units in the field. This direct feedback is used to improve and upgrade the fielded systems and to increase functionality, utility, acceptability and performance.

|

The HOOAH! bar is a nutrition-dense energy snack. The ingredients are similar to those found in commercially-sold energy bars. |

The results of user suggestions and field evaluation drive the changes to the MRE. These rapidly-fielded, customer-focused improvements are possible through the effective use of the Combat Ration Integrated Product Team (CR-IPT), whose key members include the customer, combat developer, vendors, materiel developer and procurement agency.

Since 1993, more than 80 new items, 70 percent of which are non-developmental commercial items, were approved for the MRE, while 16 items were replaced.

Many new MRE component items were recently approved by the Joint Service Operational Ration Forum Integrated Process Team for inclusion in MRE XXI.

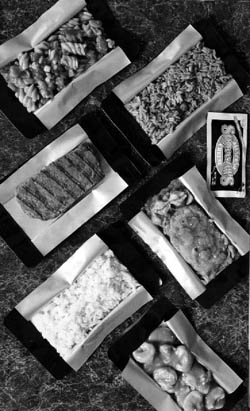

New entrée items developed at Natick and recommended and approved for MRE XXI production include jambalaya and enchilada. In addition, several new entrées were approved to be used as needed, including chicken nuggets with cavetelli, mesquite chicken breast and beef steak with mushroom gravy. Additional approved items include wheat snack bread, plain snack, mashed potatoes added as a starch in applicable menus, spice pound cake, peanut butter cookies, pretzels filled with nacho cheese and cheddar cheese, chocolate chip cookies and snack cereals.

These items may be added during menu planning at the discretion of Combat Feeding Program food technologists.

Finally, a new light-green camouflage color was approved for the MRE retort pouch, which provides a readily producible product with increased camouflage properties for reduced signature.

Continual improvements

The people behind the MRE-the scientists, food technologists, and producers-are not sitting still as efforts to improve the ration and meet the changing needs and demands of the military customer are ceaseless.

The range, diversity and innovation in menu planning, as infused in the MRE program to best meet the changing demographics of the military population, is clear indication of the steadfast commitment to continual product improvement and customer focus to satisfy user requirements.

A continual product improvement program will further enhance all fielded individual rations by evaluating new items and preparing and transitioning performance based requirements to the Defense Logistics Agency's Defense Supply Center Philadelphia for procurement.

|

Gen. Henry Shelton, chairman of the Joint Chiefs of Staff, samples MRE food while Gerald Darsch, DoD Combat Feeding Program director, describes the entrees. |

Numerous compliments have been received on the quality, variety and innovation being applied to the MRE.

In a ration sampling provided to some of the military's highest ranking officers assembled in the National Military Command Center at the Pentagon, Gen. Henry Shelton, chairman of the Joint Chiefs of Staff, perhaps summed it up best.

"The modern technology we've got today and continuing to improve ...it's absolutely phenomenal...as close to home cooking as you can get," said Shelton.

|

New entrée items developed at the U.S. Soldier Systems Center (Natick) and recommended and approved for MRE XXI production include jambalaya and enchilada. |

Current and future initiatives will provide the technology to continually improve the MRE so that it provides the warfighter with sustained energy, mental alertness and eat-on-the-move capability. The DOD Combat Feeding Program works daily to uncover new solutions and capabilities that leverage revolutionary technologies and provide fully integrated systems supporting U.S. military objectives.

January 2000

| Bulletin Board | Keyword Search |

| Bookstore | Links |

| About Us | Recent Additions |

![]()